Weld Neck Flange 900# RF A182 F91

ASME B16.5 Weld Neck Flange

This page covers weld neck flange 900# dimensions and weights according to ASME B16.5, as well as dimension ranges and material grades for forged steel flanges.

Weld neck flange has a long tapered hub which goes gradually to the thickness of pipes it connected and provide an important reinforcement. It is widely used in industrial pipe system and suitable for high pressure, sub-zero or elevated temperatures applications.

Zizi is China leading manufacturer and exporter of forged steel flanges and pipe fittings, we have a large number of stocks of weld neck flanges class 900 ASTM A182 F91.

Weld Neck Flange Advantages

- Hard to be deformed

- Great Leak proof

- Good weld-ability

- Extensive apply range

- Weld neck flange 900# withstand high pressure and large temperature fluctuations

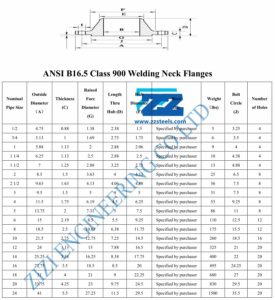

Class 900 Weld Neck Flange Dimensions

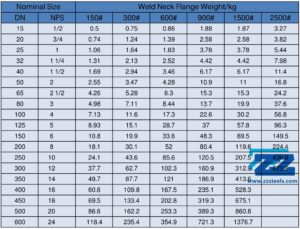

Weld Neck Flange Weight

Supply Range of Forged Steel Flanges

| Standard | ASME B16.5, ANSI B16.47 Series A, B16.47 Series B WN Flange 900# |

|---|---|

| Diameter | 1/2 to 24 Inch / DN15 — DN600 |

| Schedule | Class 150, 300, 600, 900, 1500, 2500 |

| Seal Face | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF) for WN Flange 900# |

| Seal Thickness | Sch 10S, 20, STD, 40, XS, 80, 160, XXS |

Material Grades for Weld Neck Flange 900#

Copper Nickel Alloy WN Flange 900#

Monel 400/ 405/ K500, NICKEL 200/ 201, INCONEL 825/ 600/ 601/ 625, HASTELLOY C 276, UNS C70600, C71500

Stainless Steel Weld WN Flange 900#

ASTM A182 F304/304L/304H, 316/316L/316H, 321, 310/310S, 317,347

Carbon Steel WN Flange 900#

ASTM A105/A105N, A350 LF2/LF3, A694 F52, F65, F70

Alloy Steel WN Flange 900#

ASTM A182 F1, F5, F9, F11, F12, F22, F91

Duplex Steel WN Flange 900#

ASTM A182 F51, F53, F55, F60

Services for Forged Steel Flanges

Quality Control

Offer in-factory inspection and third party inspection, offer MTC for forged weld neck flanges.

Package

Wrapped WN Flange 900# with plastic film, supply wooden cases for small diameter flanges and wooden pallet for larger sizes.

Delivery

Ship or courier

Certificate

CE, ISO, TEST REPORT

ASTM A182 F91 Properties

Chemical Composition

| C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.08-0.12 | 0.3-0.6 | 0.01 | 0.02 | 0.2-0.5 | 8-9.5 | 0.85-1.05 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 585 (Mpa) | 415 (Mpa) | 20 (%) |

此站点遇到了致命错误。