Threaded Coupling 3/4” Class 3000

3/4″ Threaded Coupling

| Standard | ASME B16.11 |

|---|---|

| Type | Half Coupling and Full Coupling |

| Diameter | 3/4” Socket |

| Pressure | 3000LB, 6000LB, 9000LB |

| Thread | NPT, BSPP, BSPT |

| Material | ASTM A182 F316L |

ISO Certified manufacturer and exporter Zizi offers 3/4” Threaded Coupling BSPP Class 3000 Stainless Steel 316L ASME B16.11 for South Africa.

Forged Coupling is an important fittings that threaded or socket weld connected pipes with other pipes or fittings. It also called “socket” in some regions. Both threaded coupling and socket weld coupling are leak proof and the former is quick installation and easy usage. 3/4″ socket has two female thread ends and the ends has same diameter. If the two ends are of different sizes is called a reducing coupling or reducer.

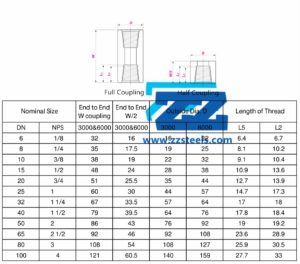

Threaded Coupling Dimensions

- TDimensions is accordance with ASME B16.11.

- The thread is machined per ASME B1.20.1.

- Offer 3/4″ socket in stainless steel, carbon steel, alloy steel, copper alloy and nickel alloy.

3/4” Threaded Coupling Quality Control

In Factory Inspection

- Clear and Correct Marking, such as “Socket 3/4″ BSPP 3000LB SS316L B16.11 957”

- Even and Smooth Surface

- Measure Dimensions in tolerance. Covers the size of outside and inside diameter, end to end length and thread length.

- Test the threads and chemical composition of SS316 3/4″ threaded coupling.

Third Party Inspection

- BV, SGS, LR, DNV, ABS

Certificate

- CE, ISO, TEST REPORT and stamp mill test certificate.

Advantages of Stainless Steel Forged Fittings

Stainless steel forged fittings is known for the long service and excellent corrosion resistance. It withstand corrosion of oxygen, water and most acid substance. Stainless steel fittings also have great strength and performance. The common used stainless steel grades have

- A182 F304/ 304H/ 304L, F316/ 316L/ 316H, F310/ 310S, F321, F317,347.

SS316L is less carbon type of SS316. Stainless Steel 316L has better weld ability, strength than stainless steel 316.

How to Test the Threads of Threaded Fittings?

A182 F316L Properties

SS316L Chemical Composition

| C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|

| 0.03 | 2 | 1 | 0.04 | 0.03 | 16-18 | 10-14 |

SS316L Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 515 (Mpa) | 205 (Mpa) | 30 (%) |

此站点遇到了致命错误。