Stainless Steel Stub End Long Type

Stainless steel lap joint stub end is available in long pattern and short pattern from size 1/2” to 24”, accept customized dimension and materials.

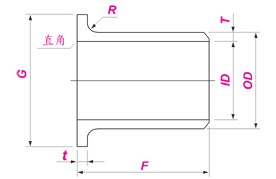

Lap joint stub end is a short pipe or tube with one end stretch outwards like a hat and one end is plain or beveled. It has many types according to the application. Rotating back up flanges are usually used with stub end. The lap thickness can be larger than or same as that of pipe wall.

Zizi is an ISO certified manufacturer of wrought fittings, forged pipe fittings and flanges, our products are high quality and durable, they all qualified and supplied with mill test certificates.

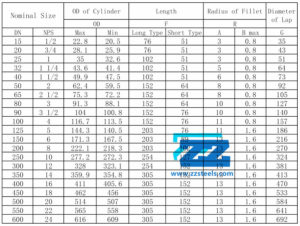

Stainless Steel Stub End Dimensions

Type: Long pattern lap joint stub end

Standard: ASME B16.9

Diameter: 6”

Schedule: Sch40

OD: 167.5-171.3

F: 203

R: 13

G: 216

Material: ASTM A403 WP304

Heat Treatment: Solution

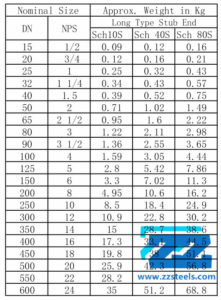

Weight of Long Type Stub End

Stub End Types

Type A stub end: Used with lap joint flanges

Type B stub end: Used with slip on flanges.

C Type : Used with both lap joint flanges and slip on flanges.

Short pattern: MSS-A stub end.

Long pattern stub end: ASA-A stub end or ANSI length stub end.

Dimensions of Lap Joint Stub End

Standard: MSS SP-43, ASME B16.9, GB/T 12459

Size: NPS 1/2 to 24 / DN 15 to 600

Thickness: Sch 10S, 40S, 80S.

Materials for Stub End

Stainless Steel Stub End

ASTM A403 WP304/304L/304H, WP316/316L, WP 309, WP310, WP317, WP321, WP347

Carbon Steel

ASTM A234 WPB, A860 WPHY42, WHPY52, WPHY60, WHPY65, WPHY70, A420 WPL 3 / 6 / 9.

Alloy Steel

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Duplex Stainless Steel

ASTM A815 UNS S 31803, 32205, 32550, 32750, 32760

Benefits of Stainless Steel Stub End

- Reducing the total cost (The material grades of stub end can be different with pipeline)

- Speed up the installation process

- Accommodates different thickness of pipes

- Beneficial to flanges recycling

- Durable

- Corrosion resistance

Why choose us

- Quickly response

- Competitive price

- High Quality

- On time delivery

- ISO Certificate

ASTM A403 WP304 Properties

Chemical Compositon,%

| C | Mn | P | S | Si | Ni | Cr |

|---|---|---|---|---|---|---|

| 0.08 | 2 | 0.045 | 0.03 | 1 | 8-11 | 18-20 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 515 MPa | 205 MPa | 30 % |

此站点遇到了致命错误。