Slip On Flange Class 150

Raised Face Slip On Flange Class 150 is commonly used and popular because of their low cost, leak proof, easy installation and high quality.

Slip on flange has a little bit larger inside diameter than the pipe outside diameter, so the flange can slip over the pipe and be welded. It helps aligned and makes the installation more easily than weld neck flanges. The flange face typically provided with raised face and flat face.

Zizi is a professional forged fittings and flanges manufacture with ISO, ABS, BV and DNV certificate. We fabricate flanges mainly according to ANSI / ASME standards.

Forged Steel Flange Dimensions

| Industrial Flanges | Slip On Flange, Screwed Flange, Socket Weld Flange, Blind Flange, Lap Joint Flange, Weld Neck Flange, Spectacle Blind. |

|---|---|

| Standard | ANSI/ASME B16.5, B16.47, API 5A |

| Diameter | 1/2” to 24”, DN15 to DN600 |

| Pressure Ratings | 150lb Slip On Flange, 300, 600, 900, 1500, 2500 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L/316H, 321, 310/310S, 317,347 |

| Carbon Steel | ASTM A105/A105N, A350 LF2/LF3, A694 F52, F65, F70 |

| Alloy Steel | ASTM A182 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Stainless Steel | ASTM A182 F51, F53, F55, F60 |

Specification of Slip On Flange Class 150

Standard: ANSI/ASME B16.5

Diameter: 1 1/2”

Pressure rating: 150lb Slip on flange

Face: RF

Schedule: SCH XS

Material: ASTM A182 F53

Heat Treatment: Solution

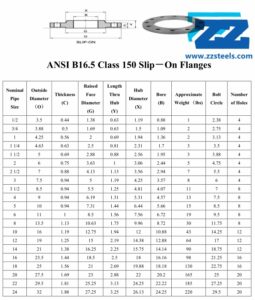

150LB Slip On Flange Dimensions

Features of Slip On Flange

- Ideal for low pressure industrial applications

- High pressure and temperature applications is OK but not recommended

- Easy to be aligned both pipes and bolting holes

- Low cost of installation

- Offered in various materials

- Slip on Flange class 150 is leak-proof

Package of ASME B16.5 Flanges

- Anti-rust oil to keep the surface in good condition

- Plastic foam to warp the flanges.

- 1 1/2” 150LB Slip on Flange is put in wooden cases. Flanges larger than 16” will be packed on wooded pallet.

Export Country

We exported 307 pieces of slip on flange 150 LB 1 1/2” ASTM A182 F53 to Greece.

- Asia: Vietnam, Singapore, Thailand, Indonesia, Malaysia, Philippines, Kazakhstan.

- Africa: Nigeria, Madagascar, Ghana, Kenya, Angola, Tanzania, South Africa.

- Middle East: Saudi Arabia, Qatar, Israel, Egypt, Oman, Yemen, Jordan, Lebanon.

- Latin America: Uruguay, Peru, Chile, Brasil, Ecuador, Colombia, Argentina, Paraguay

- Oceania: Papua New Guinea, Australia, New Zealand, Solomon Islands, Fiji.

- Europe: Greece, UK, Poland, Ukraine, France, Spain, Portugal, Norway, Sweden

ASTM A182 F53 Properties

Chemical Composition,%

| C | Mn | P | S | Si | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| 0.03 | 1.2 | 0.035 | 0.15 | 0.8 | 24-26 | 6-8 | 3-5 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 795 MPa | 550 MPa | 15 % |

此站点遇到了致命错误。