Equal Tee and Reducing Tee ASME B16.9

Buttweld Pipe Tees Manufacturer

Both equal tee and reducing tee have three branches that usually is T-shaped, they provide 90 degree branches and change fluid direction. ASME B16.9 Buttweld tees are widely used in pipe convey. They are very common in industrial applications such as oil and gas transmissions, water treatment system, power station, chemical industry and engineering.

Zizi is steel pipe fittings manufacturer and offers buttweld fittings equal tee and reducing tee in different dimensions and materials according ASME B16.9.

What is ASME B16.9 Buttweld Tees?

ASME B16.9 is manufacture standard for Factory-Made Wrought Buttwelding Fittings. Put simply it is specification for butt weld fittings.

Buttweld pipe tee connected by butt welding, which is stable than other weld type and can withstand higher pressure. Fittings ends need preparation before welding, so the end can be plain or beveled.

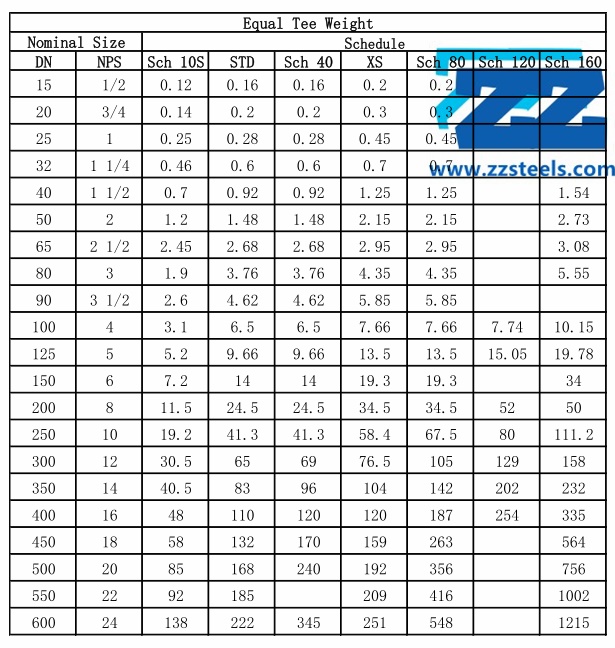

Diameter of ASME B16.9 tees is from 1/2” to 80” (DN15 to DN2000), wall thickness is specified in schedule 10S, 20, STD, 40, XS, 80, 120, 140, 160, and XXS.

What’s more, based on the production process, they are also can be divided into seamless tee and welded tee.

How many Types of Buttweld Tees?

According to the branch diameter:

- Equal Tee

- Reducing Tee

According to the production process:

- Seamless Tee

- Welded Tee

Based on the material:

- Carbon Steel Tee

- Alloy Steel Tee

- Stainless Steel Tee

- Nickel Alloy Tee

Equal Tee VS Reducing Tee

ASME B16.9 Equal Tee

- Three same sized branches, also called straight tee, or just tee.

- When you order, the description generally such as:

- Tee, 8” Sch 40 BE (beveled end) SMLE (Seamless) ASME B16.9, ASTM A403 WP304.

- Click here to check Buttweld Equal Tee Dimensions.

- ASME B16.9 equal tee weight chart.

ASME B16.9 Reducing Tee

- Has one smaller branch diameter than main pipe diameter. Named reducer tee as well.

- The description is little different with equal tees.

- The diameter usually is 8” x 6” (or 8” x 8” x 6”). The larger sizes usually considered as the main pipe size.

- Wall thickness of larger branch and smaller branch can be same or different. That is it can be Sch 40 or Sch 40 x Sch 80.

- Other descriptions like end type, technique, standard and material are the same.

- Click here to check Buttweld Reducing Tee Dimensions.

- Weight of reducing tee is calculated on the basis of the weight of equal tees.

Features of Buttweld Equal Tee and Reducing Tee

- Leak-proof

- Cost Advantage

- Large Dimension Range

- Durable

- Dimensional Accuracy

Seamless Tee VS Welded Tee

Cold drawn for seamless tees and Seam welding for welded tees.

Generally speaking, seamless tee is more prevalent now and welded tee mostly is large diameter tee.

Materials for Straight & Reducing Tee

Carbon Steel Equal Tee & Reducing Tee

They have obviously cost advantages, usually have coating such as galvanized, PE, black primer.

A234 WPB, A420 WPL3,WPL6, WPL9, WPHY42, WHPY52, WPHY60, WHPY65, WPHY70

Alloy Steel Equal Tee & Reducing Tee

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Stainless Steel Equal Tee & Reducing Tee

They are known for the excellent corrosion resistance and long service life.

A403 WP304/304L, WP316/316L, WP321, WP317, WP310

Nickel Alloy Equal Tee & Reducing Tee

Nickel alloy pipe fittings have great resistance to acid and oxygen corrosive.

ASTM / ASME SB 336, SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ), UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C276)

Supply Range for Buttweld Fittings

| Standard | ASME B16.9, GB/T12459, GB/T13401, SH3408, HG/T21635, HG/T21631, SY/T0510 |

|---|---|

| Product | 90 Degree Elbow, 45 Degree Elbow, 180 Degree Elbow. Steel Bend. Equal Tee, Reducing Tee, Pipe Cap, End Cap, Concentric Reducer, Eccentric Reducer, Stub End. |

| Size | DN15 to DN1500, NPS 1/2” to NPS 60” |

| Schedule | Sch 10S, 20, STD, 40, XS, 80, 100, 120, 160, XXS |

| End | PE, BE |

| Type | Seamless, Welded |

此站点遇到了致命错误。