90° Steel Pipe Elbow Types, Dimensions and Weights

90° Steel Pipe Elbow

90° Steel Pipe Elbow is the most commonly used elbow type in pipe system with the function to change the direction of fluid in 90 degree. It connects pipes with same or different diameter.

This kind of elbow is classified by angle, and 45 degree elbow and 180 elbow is also very popular. And steel pipe elbow is also available in 60 degree, 30 degree and other special angle according to practical needs.

Except the angle, steel pipe elbows can be divided into diverse types based on different factors. Here we will use 90 degree elbow to show how they classified according to other factors.

How to Classify 90 Degree Pipe Elbow

We mainly divide steel pipe elbows according to

- Angle

- Radius

- Connection

- Material

Since our focus is on 90 degree steel pipe elbow, we will discuss 2, 3 and 4 in details.

Long Radius Elbow and Short Radius Elbow

Radius refers to curvature radius of 90° Steel Pipe Elbow. It typically has long radius and short radius two types. It is a necessary elements to descrip buttweld elbows.

-

Long radius 90 Degree Elbow

In contrast, long radius 90° steel pipe elbow is more common, the radius is 1.5 times of pipe diameter (R=1.5D). It is usually used in high pressure or fast flow rate pipelines.

Generally speaking, if the elbow radius is not mentioned, we usually regard it as long radius elbow.

When the radius larger than 1.5D, they will be expressed as R=3D, 5D, 10D……even someone also call them long radius elbow.

-

Short Radius 90 Degree Elbow

It means the radius is equal to the pipe diameter ( R=1D). Short radius elbow also looks shorter than long radius elbow, and it is applied in low pressure fluid pipe system or where elbow conditions are limited.

Connections Types of Steel Pipe Elbow

According to the connection way, there are Buttweld Elbow, Socket Weld Elbow and Threaded Elbow.

Buttweld 90° Elbow

Butt weld elbow is directly welded with pipes. For the purpose of easy welding, its end usually is beveled, but also available in plain end. Based on the produce process, it also has seamless and welded types.

The advantages of buttweld 90° steel pipe elbow are it has large dimension ranges and strong structure as well as withstand higher pressure than other connection types.

Suppry Range

| Standard | ASME B16.9 |

|---|---|

| Diameter | NPS 1/2” to 80”, DN15 to DN2000 |

| Wall thickness | Schedule 10S, 20, STD, 40, XS, 80, 120, 160, XXS |

| Radius | LR, SR, R=3D, 5D, 10D or as customer requires |

| End | Plain End (PE), Beveled End (PE) |

| Type | Seamless, Welded |

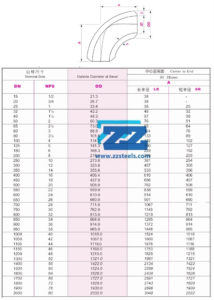

Buttweld 90° Elbow Dimensions

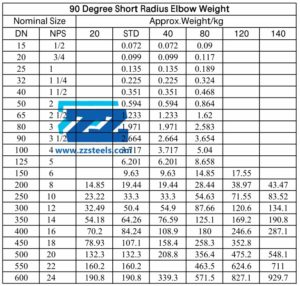

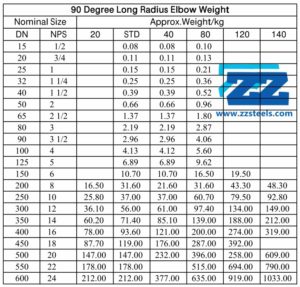

Buttweld 90° Elbow Weight

Socket Weld 90° Elbow

Socket weld elbow has a trapezoidal area at the end for inserting the pipe, and then pipes and socket weld elbow will be fillet welded together.

The advantages of socket weld 90° steel pipe elbow are it is free to align and beveled for welding, leak-proof, and withstand to high pressure and temperature.

Suppry Range

| Standard | ASME B16.11, BS3799 |

|---|---|

| Diameter | 1/8”, 1/4”, 3/8”, 1/2” 3/4” 1”, 1 1/4”, 1 1/2”, 2”, 2 1/2”, 3”, 4” |

| Wall Thickness | Class 3000, 6000, 9000 |

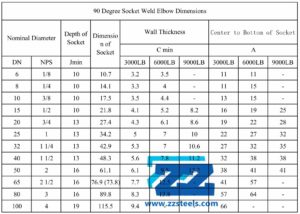

90° Socket Weld Elbow Dimensions

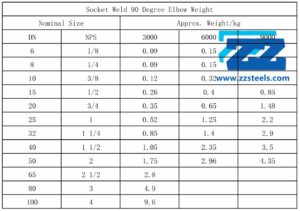

90° Scoket Weld Elbow Weight

Threaded 90° Elbow

Threaded elbow and socket weld elbow are both forged steel elbow, so the are similar in shape and dimensions. It has internal threads to connect with pipes with external threads.

The advantages of threaded 90° steel pipe elbow are simple to use and easy installation and maintenance.

Suppry Range

| Standard | ASME B16.11, BS3799 |

|---|---|

| Diameter | 1/8”, 1/4”, 3/8”, 1/2” 3/4” 1”, 1 1/4”, 1 1/2”, 2”, 2 1/2”, 3”, 4” |

| Wall Thickness | Class 2000, 3000, 6000 |

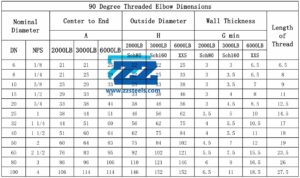

90° Threaded Elbow Dimensions

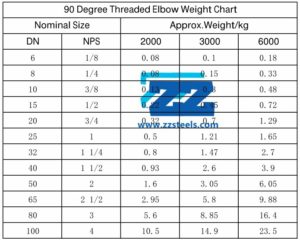

90° Threaded Elbow Weight

Material Grades for 90° Steel Pipe Elbow

Stainless Steel Pipe Fittings

Stainless steel pipe fittings are known for the excellent corrosion resistance and long service life. The common used grades are:

ASTM A403 WP304/304L, WP316/316L for buttweld 90 Degree Elbow

ASTM A182 F304, F316, F310, F321 for forged elbows.

Carbon Steel Pipe Fittings

Carbon steel pipe fittings are very commonly used because their obvious cost advantages.

ASTM A234 WPB, A860 WPHY42/52/60/65, A420 WPL3/6/9 for 90 Degree Elbow

ASTM A105/105N, A350 LF2,LF3. A694 F52, F60, F65, F70 for forged elbows.

Alloy Steel Pipe Fittings

The features of alloy steel is the great comprehensive properties and various characteristics

A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91 for buttweld 90 Degree Elbow

ASTM A182 F1, F5, F9, F11, F12, F22, F91 for forged elbows

Besides, we also offer Dduplex Stainless Steel, Nickel Alloy and Copper Alloy pipe fittings.

此站点遇到了致命错误。