Spiral Wound Gasket is the most common metallic gasket used in industrial plants. A properly selected and installed spiral wound gasket can withstand high temperatures and pressures, preventing leaks throughout their intended lifespan.

The spiral wound gasket has good sealing performance. Its spiral winding structure allows the metal belt and filling material to fit tightly on the sealing surface when the gasket is under pressure, filling the tiny unevenness of the sealing surface, thereby effectively preventing medium leakage.Spiral wound gaskets are widely used in the sealing of flange connections of pipelines, valves, pressure vessels, condensers, heat exchangers and other equipment in the petroleum, chemical, metallurgy, electric power, shipbuilding, machinery and other industries.

ASME B16.20 Standard

This Standard covers materials,dimensions, tolerances, and markings for metal ring-joint gaskets, spiral-wound metal gaskets, metal-jacketed gaskets, and grooved metal gaskets with covering layers. These gaskets are dimension ally suitable for use with flanges described in reference flange standards ASME B16.5,ASME B16.47, API Specification 6A, and ISO 10423.

Spiral Wound Gasket

Spiral wound gasket, including centering ring and inner ring (paras.3.2.4 and 3.2.5), are identified by flange size (NPS),pressure class, and the appropriate flange standard(ASME B16.5 or ASME B16.47).

Dimensions and Tolerances

Dimensions and tolerances for spiral wound gasket, centering rings, and inner rings shall be in accordance with Tables 9 through 14 (Tables I-4through I-9 of Mandatory Appendix I) and as specified in this section (see also Figs. 1 and I-1).

Construction

Spiral-wound gaskets shall be constructed as alternate plies (circular layers counted as revolutions)of preformed metal windings and pliant fillers that are spirally wound. For the finished gasket,the filler shall be essentially flush with, but not below,the metal winding on both contact faces of the gasket.The metal strip in the winding shall be 0.15-mm(0.006-in.)to 0.23-mm(0.009-in.) thick.The filler material thickness shall be determined by the manufacturer.

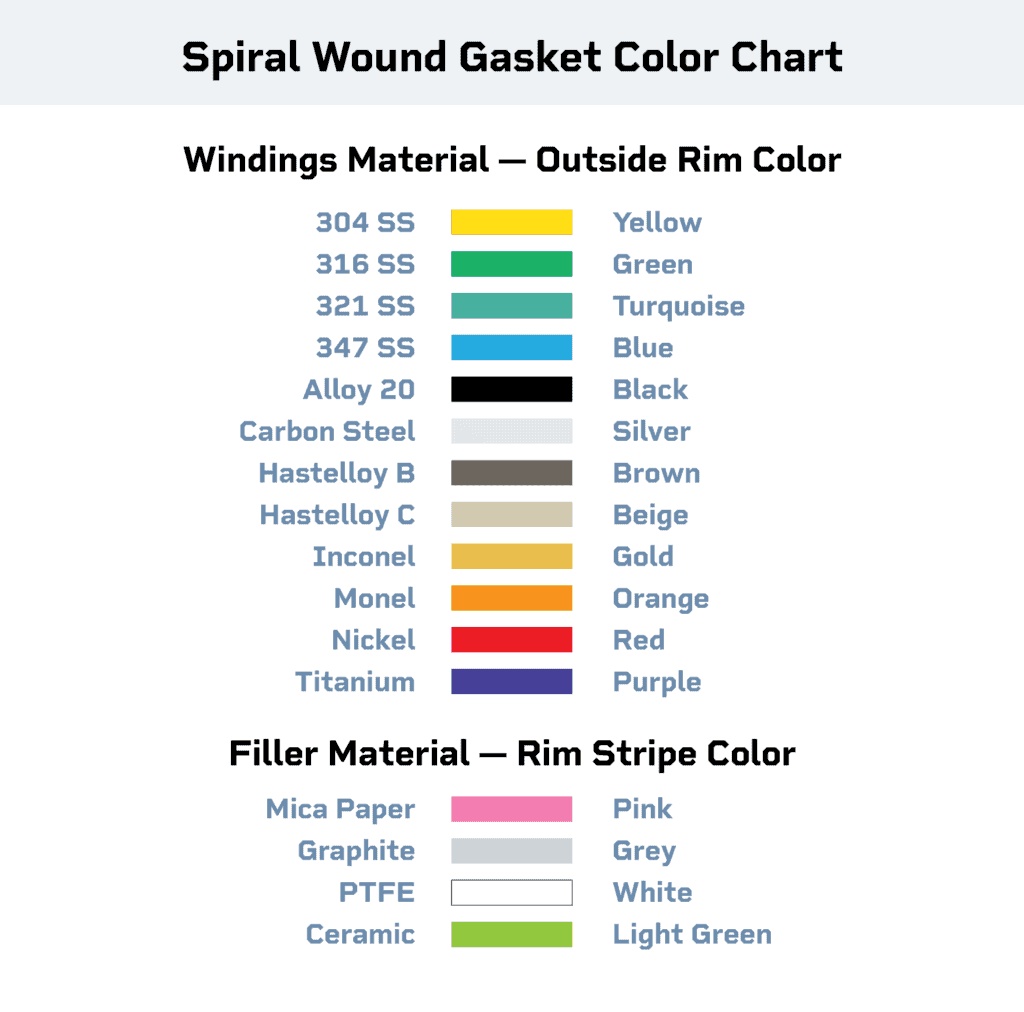

Spiral Wound Gasket Color Codes

Spiral Wound Gasket Dimension

| Table 9 Dimensions for Spiral-Wound Gaskets Used With ASME B16.5 Flanges | ||||||||||||||||

| Outside Diameter of Gasket [Note(1)] |

||||||||||||||||

| Flange Size (NPS) |

Classes 150,300, 400,600 |

Classes 900,1500, 2500 |

Inside Diameter of Gasket by Class [Notes(2). (3)] | Outside Diameter of Centering Ring by Class [Note(4)1 | ||||||||||||

| 150 | 300 | 400(5) | 600 | 900(5) | 1500 | 2500 (5) | 150 | 300 | 400(5) | 600 | 900(5) | 1500 | 2500(5) | |||

| 1/2 | 31.8 | 31.8 | 19.1 | 19.1 | 19.1 | 19.1 | 19.1 | 47.8 | 54.1 | 54.1 | … | 63.5 | 69.9 | |||

| 3/4 | 39.6 | 39.6 | 25.4 | 25.4 | 25.4 | 25.4 | 25.4 | 57.2 | 66.8 | 66.8 | 69.9 | 76.2 | ||||

| 1 | 47.8 | 47.8 | 31.8 | 31.8 | 31.8 | 31.8 | 31.8 | 66.8 | 73.2 | 73.2 | 79.5 | 85.9 | ||||

| 1 1/4 | 60.5 | 60.5 | 47.8 | 47.8 | 47.8 | 39.6 | 39.6 | 76.2 | 82.6 | 82.6 | 88.9 | 104.9 | ||||

| 1 1/2 | 69.9 | 69.9 | 54.1 | 54.1 | 54.1 | 47.8 | 47.8 | 85.9 | 95.3 | 95.3 | 98.6 | 117.6 | ||||

| 2 | 85.9 | 85.9 | 69.9 | 69.9 | 69.9 | 58.7 | 58.7 | 104.9 | 111.3 | 111.3 | 143.0 | 146.1 | ||||

| 2 1/2 | 98.6 | 98.6 | 82.6 | 82.6 | … | 82.6 | 69.9 | 69.9 | 124.0 | 130.3 | … | 130.3 | 165.1 | 168.4 | ||

| 3 | 120.7 | 120.7 | 101.6 | 101.6 | 101.6 | 95.3 | 92.2 | 92.2 | 136.7 | 149.4 | 149.4 | 168.4 | 174.8 | 196.9 | ||

| 4 | 149.4 | 149.4 | 127.0 | 127.0 | 120.7 | 120.7 | 120.7 | 117.6 | 117.6 | 174.8 | 181.1 | 177.8 | 193.8 | 206.5 | 209.6 | 235.0 |

| 5 | 177.8 | 177.8 | 155.7 | 155.7 | 147.6 | 147.6 | 147.6 | 143.0 | 143.0 | 196.9 | 215.9 | 212.9 | 241.3 | 247.7 | 254.0 | 279.4 |

| 6 | 209.6 | 209.6 | 182.6 | 182.6 | 174.8 | 174.8 | 174.8 | 171.5 | 171.5 | 222.3 | 251.0 | 247.7 | 266.7 | 289.1 | 282.7 | 317.5 |

| 8 | 263.7 | 257.3 | 233.4 | 233.4 | 225.6 | 225.6 | 222.3 | 215.9 | 215.9 | 279.4 | 308.1 | 304.8 | 320.8 | 358.9 | 352.6 | 387.4 |

| 10 | 317.5 | 311.2 | 287.3 | 287.3 | 274.6 | 274.6 | 276.4 | 266.7 | 270.0 | 339.9 | 362.0 | 358.9 | 400.1 | 435.1 | 435.1 | 476.3 |

| 12 | 374.7 | 368.3 | 339.9 | 339.9 | 327.2 | 327.2 | 323.9 | 323.9 | 317.5 | 409.7 | 422.4 | 419.1 | 457.2 | 498.6 | 520.7 | 549.4 |

| 14 | 406.4 | 400.1 | 371.6 | 371.6 | 362.0 | 362.0 | 355.6 | 362.0 | 450.9 | 485.9 | 482.6 | 492.3 | 520.7 | 577.9 | ||

| 16 | 463.6 | 457.2 | 422.4 | 422.4 | 412.8 | 412.8 | 412.8 | 406.4 | … | 514.4 | 539.8 | 536.7 | 565.2 | 574.8 | 641.4 | |

| 18 | 527.1 | 520.7 | 474.7 | 474.7 | 469.9 | 469.9 | 463.6 | 463.6 | 549.4 | 596.9 | 593.9 | 612.9 | 638.3 | 704.9 | ||

| 20 | 577.9 | 571.5 | 525.5 | 525.5 | 520.7 | 520.7 | 520.7 | 514.4 | 606.6 | 654.1 | 647.7 | 682.8 | 698.5 | 755.7 | ||

| 24 | 685.B | 679.5 | 628.7 | 628.7 | 628.7 | 628.7 | 628.7 | 616.0 | 717.6 | 774.7 | 768.4 | 790.7 | 838.2 | 901.7 | ||

Installation of Spiral Wound Gaskets

Before installing the spiral wound gasket, you need to carefully check the integrity of the gasket. Check whether the metal belt is damaged or broken, whether the filling material has fallen off, etc.

It is very important to thoroughly clean the sealing surface and the gasket installation area. Remove impurities such as oil, rust, dust, etc. on the sealing surface.

Place the spiral wound gasket correctly on the sealing surface. Make sure that the center of the gasket is aligned with the center of the sealing surface.

When installing the bolts, a symmetrical and gradual tightening method should be adopted. First, lightly screw all the bolts into the screw holes to initially position the gasket. Then follow the diagonal order and tighten the angle a small amount each time to gradually increase the tightening force of the bolts.

After installation, you need to check the installation of the gasket again. Check whether the gasket is still in the correct position without offset or distortion.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....