Flanges, bolts and gaskets are used in combination. Flange is an important part of pipeline connection, which provides a relatively flat sealing surface. Gasket is placed between two flanges, and its main function is to fill the small gap between the flange sealing surfaces. Bolts are used to connect two flanges, and by tightening the bolts, pressure can be applied to the gasket. Appropriate bolt tightening force is one of the key factors to ensure the sealing effect.

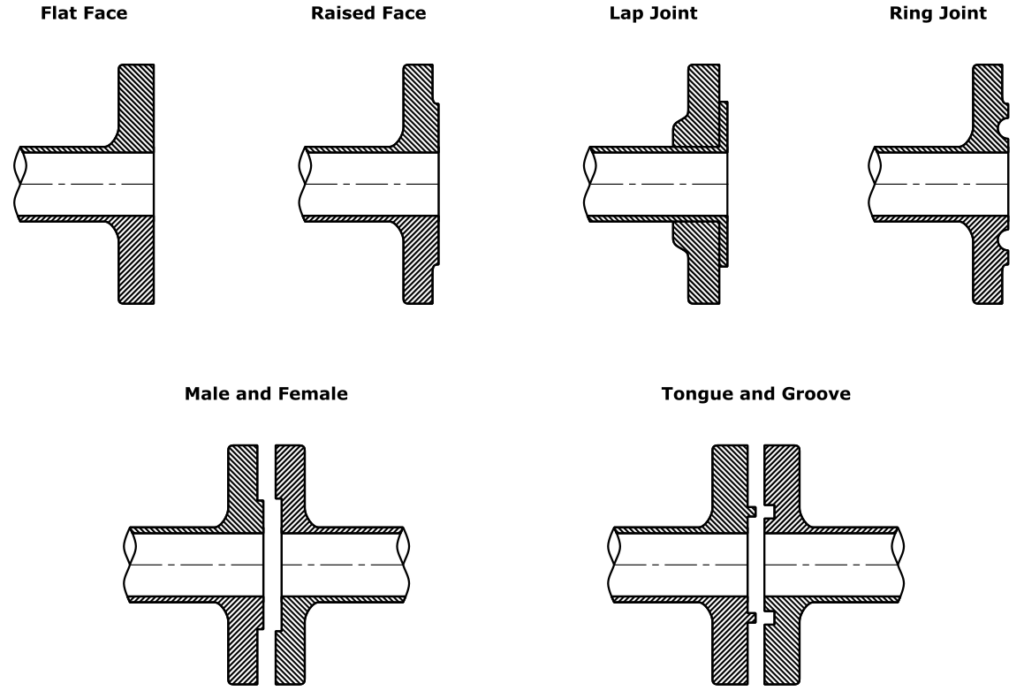

Flanges Faces

Male and Female Face (MFM) -It has high requirements for the dimensional accuracy of the gasket. The outer diameter of the gasket should match the outer diameter of the concave face, and the inner diameter should match the inner diameter of the convex face. Metal gaskets or semi-metallic gaskets, such as spiral wound gaskets, are usually used.

Tongue and Groove Face (TG) -Ihas extremely strict requirements on the shape and size of the gasket. The gasket should be accurately embedded in the tenon groove, and its thickness should be adapted to the depth of the tenon groove.

Flat Face (FF) – Sealing is also by compression of a flat non-metallic gasket, between the phonographic/ concentric grooved surfaces of the mating FF flanges. The gasket fits over the entire face of the flange.

Raised Face (RF) – Sealing on a RF flange is by a flat non-metallic gasket,which fits within the bolts of the flange. The facing on a RF flange has a concentric or phonographic groove with a controlled surface finish.

Ring Type Joint (RTJ) – Typically found on the most severe duties, for example high pressure gas pipework. Ring type metal gaskets must be used.

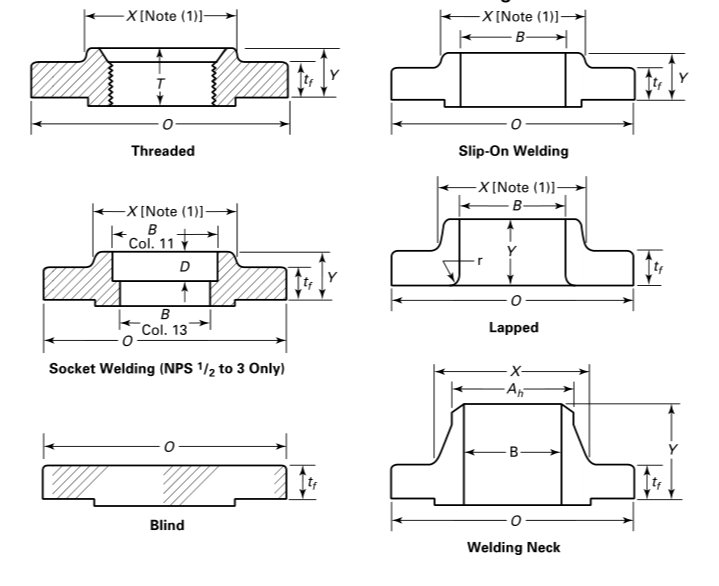

Flanges Types

Flanges types can be roughly divided into six categories, namely blind flange, weld neck flange, socket weld flange,threaded flange,lap joint flange,slip on flange.

Flange Gaskets Types

Flange gaskets are compressible sheets or rings used to make a fluid-resistant seal between two surfaces. Gaskets are built to operate under extreme temperature and pressures and are available in a wide range of metallic, semi-metallic and non-metallic materials.

Non-metallic Gaskets

Rubber Gaskets

Rubber gaskets have good elasticity and sealing properties. Its elasticity enables it to deform under a small bolt tightening force and fill the gap between the flange sealing surfaces.

PTFE Gaskets for Flange

PTFE gaskets have excellent chemical stability and are almost not corroded by all chemicals, except for very few substances such as molten alkali metals.

Semi-metallic Gaskets

Spiral Wound Gaskets for Flange

Spiral wound gaskets are wound by metal strips and non-metallic filling materials. It combines the strength of metal and the sealing properties of non-metal. The metal strip provides the structural strength of the gasket and can withstand high pressures and temperatures, while the non-metallic filling material plays the role of filling the gap between the sealing surfaces.

Metal Jacketed Gasket

Metal Jacketed gaskets are a layer of metal sheet coated on the outside of a non-metallic core material . This type of gasket has good corrosion resistance and high strength.

Metallic Gasket

Oval Ring Gasket for Flange

The shape of the oval ring metal gasket gives it a unique advantage in sealing. It can achieve a more uniform pressure distribution under the action of the bolt tightening force.

Octagonal Ring Gasket

The octagonal ring metal gasket has an octagonal ring shape. The octagonal design allows the gasket to be better positioned during installation and evenly transfers pressure to the flange sealing surface when under pressure. Each corner of the octagonal ring is precisely machined to ensure a good fit with the flange surface.

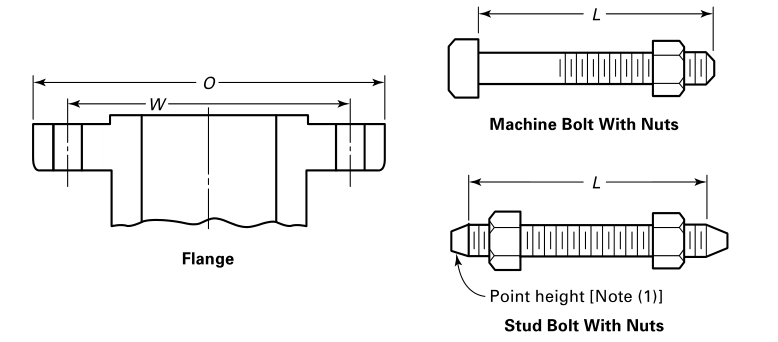

Flange Bolts

There are bolt holes on the flange, and the flange bolts connect the two flanges together through these bolt holes. The gasket also needs to have a corresponding structure to accommodate the existence of the bolt holes. Flanges, gaskets and bolts are integrated. For example, for a circular flange and gasket, the bolt holes are evenly distributed on the circumference, and the position of the bolt holes on the gasket must completely correspond to those on the flange.

Bolt Tightening

Bolts are used to connect two flanges.Flanges, gaskets and bolts need to fit tightly. By tightening the bolts, pressure is applied to the gasket. Appropriate bolt tightening force is one of the key factors to ensure the sealing effect. If the tightening force is insufficient, the gasket cannot be fully deformed to fill the gap between the sealing surfaces. But excessive tightening force may damage the gasket or deform the flange, which will also affect the sealing effect.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....