Weldolet MSS SP 97 Dimensions, SS 304 Weldolet Specification

Weldolet MSS SP-97

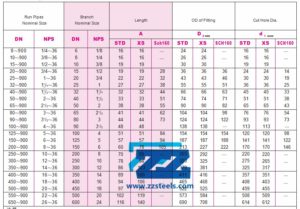

Weldolet is available in branch sizes from 1/8” to 24”, run pipe sizes from 1/4” to 36”, schedule STD, XS and Sch 160 according to MSS SP-97.

MSS SP-97 Weldolet has beveled ends at both end usually the larger side is for run pipe and the smaller side for branch pipe. It designed to create a 90 degree reinforced branch with minimized stress concentrations. Reducing tee has the same function but it needs a reinforcing weld.

Zizi offers full size range outlet branch connection pipe fittings in various grades of stainless steel, carbon steel and alloy steel.

Weldolet Dimensions Chart

MSS SP 97 Weldolet Material Grade

Stainless Steel MSS SP 97 Weldolet

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Carbon Steel Weldolet

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Duplex & Super Duplex Steel Weldolet MSS SP 97

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950

Installing a Weldolet

- Preparation: Beveled the end and align.

- Lay out: Template is inside of the fittings

- Cut Hole: Cut a hole on the run pipe before or after weldolet is welded on.

- Establish proper weld gap by placing spacers or welding rods.

- Tack Weld: It is better to tack welded the joint at four points. Remove the spacers.

Weldolet Ordering Information

Item: Weldolet MSS SP-97

Size: 6” STD

Material: ASTM A182 F304

Quantity: 425 PCS

Lead Time: 15 days for shipping

Package: Anti rust oil, plastic bag, carton box, wooden cases

Inspection: QA/QC, Third Party Inspection

Document: CI, PL, CO, BL, MTC

Certificate: CE, ISO, TEST REPORT

ASTM A182 F304 Properties

ASTM A182 F304 Chemical Composition

| C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|

| 0.03 | 2 | 0.75 | 0.045 | 0.03 | 18-20 | 8-10.5 |

ASTM A182 F304 Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 515 (Mpa) | 205 (Mpa) | 40 (%) |

此站点遇到了致命错误。