24″ Welded Pipe Cap ASTM A234 WP9

Large Diameter Pipe Cap

Large diameter 24″ Welded Pipe Cap Sch 80 ASTM A234 WP9 is sold to Vietnam along with DN800 90 degree elbow and stainless steel concentric reducer.

Buttweld pipe fittings is extensive used because the large dimension ranges and the stable joint. It plays an important role especially in pipe systems more than 4”. Buttweld cap can be divided into seamless cap and welded cap.

Zizi is manufacturer and exporter of large diameter buttweld fittings with advanced technology and perfect service.

Buttweld Fittings Dimensions

| Standard | ASME / ANSI B16.9, SY/T0510, HG/T21631, SH3408, GB/T13401, GB/T12459 |

|---|---|

| Diameter | NPS 1/2 to NPS 48, DN15 to DN1200 |

| Schedule | Sch 10S, 20, STD, 40 XS, 80, 120, 160, XXS |

| Products | 90 Degree Elbow, 45 Degree Elbow, Return Elbow, Bend, Equal & Reducing Tee, Concentric and Eccentric Reducer, Seamless and Welded Pipe Cap, Stub End. |

| Surface | Black Primer, Galvanized, PE Coating |

Material Grades for 24″ Welded Pipe Cap

Stainless Steel

ASTM A403 WP304/304L/304H, 316/316L/316H, 321, 310/310S, 317,347

Carbon Steel

ANSI / ASTM A234 WPB, A420 WPL3,WPL6, WPL9,

A860 WPHY42, WHPY52, WPHY60, WHPY65, WPHY70,

24″ Welded Pipe Cap Alloy Steel

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Duplex & Super Duplex Steel

S 31803, S 32205, S 32550, S 32750, S32760

Nickel Alloy

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

Copper Alloy Steel

ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C70600 ( CU -NI- 90/10), C71500 ( CU -NI- 70/30)

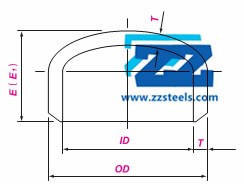

ASTM A234 WP9 24″ Welded Pipe Cap Specification

Standard: ASME B16.9

Diameter: 24”

Outside Diameter (OD): 610

Wall thickness: Sch 80

Length: E=267, E1=350

Wall Thickness for E: 12.7

Surface: Black Primer

Seamless Pipe Cap VS Welded Pipe Cap

Both seamless pipe cap and welded pipe cap are commonly used, so do you know what are their differences?

- Produce process.

- Surface: Welded cap have a welded joint at the surface, while seamless pip cap does not.

- Marking: For example, a ASTM A234 WP9 CL1 pipe cap, the grades marking will be “ASTM A234 WP9 CL1” if it is seamless, if welded, it will be marked as “ASTM A234 WP9 CL1W”.

- Application: Seamless pipe fittings can bear higher pressure than welded pipe fittings, so seamless cap always applied in high pressure applications while welded cap is mainly for medium and low pressure applications.

ASMT A234 WP9 Properties

Chemical Composition, %

| Grade | C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|---|

| WP9 CL1 & CL3 | 0.15 | 0.3-0.6 | 0.03 | 0.03 | 1 | 8-10 | 0.9-1.1 |

Mechanical Properties

| Grade | Tensile Strength | Yield Strength | Longitundinal | Transverse |

|---|---|---|---|---|

| WP9 CL1 | 414-585 MPa | 205 MPa | 22 % | 14 % |

| WP9 CL3 | 520-690 MPa | 340 MPa | 22 % | 14 % |

此站点遇到了致命错误。