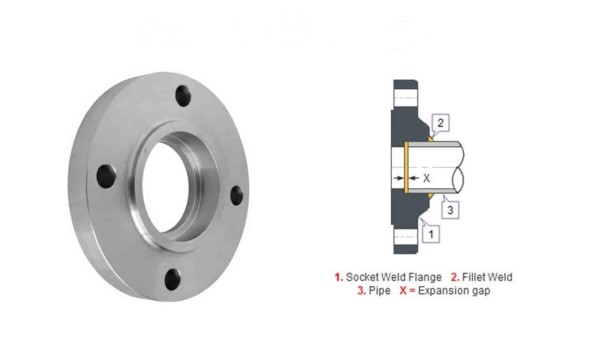

What is Socket Weld Flange?

Socket Weld Flange is a method of connecting pipes, valves, pumps and other equipment to form a pipe system. They are bolted together with a Gasket between them to provide a seal. It has the function of easy access for cleaning, inspection and modification.

Flanges are bolted with gasket

ASME B16.5 Socket Weld Flange has a recessed shoulder at the inner bore, so the pipe can be insert in the shoulder correctly and easy to weld. This welding structural essentially providing a smooth bore and a good transmission performances for the liquid in the pipelines.

ASME B16.5 Flange

ASME B16.5 Pipe Flanges include Slip On Flange, Weld Neck Flange, Socket Weld Flange, Threaded Flange, Lap Joint Flange and Blind Flange. Flanged Fittings refer to pipe fittings with flanges.

Forged Flanges dimensions are from 1/2” to 24” and pressure are class 150, class 300, class 600, class 900, class 1500 and class 2500. To be identify easily, usually they would be shown with material and standard in the marking.

Asme b16.5 Flange

What is ASME B16.5?

The B16.5 standard was first published by ANSI in 1973. Prior to that it was an ASA standard. In 1996 the standard changed to ASME B16.5

ASME B16.5 is the standard for pipe flanges and flange fittings. It was made by American Society of Mechanical Engineers, who has been defining piping safety since 1922.

This standard covers the pressure-temperature ratings, materials, dimensions, tolerances, marking, testing, and methods of designating openings for pipe flanges.

ASME B16.5 Socket Weld Flange Dimensions

| Pressure | Diameter |

|---|---|

| Class 150, 300, 600, 900 | NPS 1/2 to 3, DN15-80 |

| Class 1500 | NPS 1/2 to 2-1/2, DN15-65 |

| Material | Grade |

|---|---|

| Stainless Steel Flange | A182 F316/F316L, F304/F304L, A240 F310, F321 |

| Carbon Steel Flange | ASTM A105, A181 Gr 60/70, A350 F1, F2 |

| Alloy Steel Flange | A182 F1, F5, F9, F11, F12, F22, F91 |

Flange Seal Type

Seal type is necessary in the flange system. Because it can influence the application fields.

| Seal Type | Application |

|---|---|

| Raised face (RF) | General ,or PN≥10 Mpa situation |

| Male-Female-and Male (MFM) | Flammable, Explosive and Highly Hazardous situation |

| Tongue-and-Groove (T&G) | Flammable, Explosive and Highly Hazardous situation |

Socket Weld Flange Application

Forged Socket Weld Flanges were initially developed for use on small size, high pressure piping system. Their static strength is equal to Slip On flanges, but their fatigue strength 50% greater than double-welded Slip On flanges. They are mainly used in Boiler and Pressure Vessels, Oil and Gas, Chemical Industry, Shipbuilding, Metallurgy, and Engineering.

Socket Weld Flange Welding

First, insert the pipe end into the flange until it bottoms out against the shoulder, and then back the piping out between 1/16 inch and 1/8 inch. This is to prevent the expanding pipe on the inner side of the weld from expanding. It is similar to a slip-on flange, except only one fillet weld is made to the flange and pipe.

Flange Manufacturer

Zizi engineering is manufacturer and exporter of industrial flanges. We have ISO 9001 certificate and have been providing trustworthy ASME B16.5 Flanges for many years. High-class products were delivered to all our valued customers in the shortest time.

ISO 9001 Certificate

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....