What Are Flanges Used in the Oil and Gas Industry

Flanges are key parts of oil and gas pipeline systems. They are used to connect pipes, valves, pumps, and other equipment, creating a complete pipeline system. It acts like glue between pipes, securely fastening two flanges together with bolts, ensuring a strong and leak-proof connection. The flanges we produce offer excellent performance, including superior sealing, durability, heat resistance, and corrosion resistance. Additionally, our high-quality flanges help minimize maintenance and save costs.

Without flanges, oil and gas pipelines may leak and even cause serious accidents. Therefore, although flanges may seem small, they play a crucial role in industrial pipeline systems. We are a leading manufacturer of pipe fittings in China, providing high-quality flanges, elbows, bends and tees for the oil and gas industry. And we offer customized flanges in various sizes, materials, and standards to meet specific customer requirements. Feel free to contact us.

Types of Flanges Used in the Oil and Gas Industry

We specialize in the production and sales of various types of flanges used in the oil and gas industry. Depending on the classification method, our flanges can be divided into the following types:

1. Types of flanges used in the oil and gas industry based on connection type

A. Weld Neck Flange (WN):

Our weld neck flanges are commonly used in the oil and gas industry. They have a long, tapered neck that helps distribute stress evenly, making the joint stronger and more durable. This design is ideal for high-pressure and high-temperature environments. The seamless weld ensures a secure connection, reducing the risk of leaks and improving sealing. Due to these advantages, weld neck flanges are trusted in pipeline systems for reliability and safety.

B. Slip-On Flange (SO):

Our slip-on flanges feature a simple design and offer lower strength. These flanges slide over the pipe and are welded both on the inner and outer sides. Slip-on flanges are more cost-effective and easier to install than weld neck flanges. Therefore, they are often used in the oil and gas industry for auxiliary pipelines, low-pressure systems, and equipment connections, particularly when quick installation and cost efficiency are crucial.

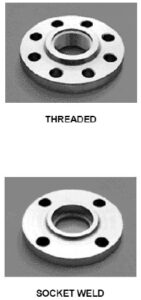

C. Threaded Flange (TF):

Our threaded flanges are less common than weld neck or slip-on flanges in the oil and gas industry, but they are important for specific low-pressure, flammable, or temporary pipelines. With internal threads, they connect directly to threaded pipes and are easier to install and remove than welded flanges. Therefore, threaded flanges are still used in some auxiliary pipelines or low-corrosion environments in the oil and gas industry.

D. The Socket Weld Flange (SW):

Our socket weld flange features a smooth inner hole, allowing the pipe to be inserted and welded for a secure connection. It has higher strength and is suitable for higher pressure environments compared to slip-on flange, though it is not as common as weld neck flange. Therefore, It is used in the oil and gas industry, mainly for small-diameter, high-pressure pipeline systems, especially where leakage prevention is critical.

E. Blind Flange (BF):

Our blind flanges have no holes, this design avoids weak spots and stress concentration, making the blind flange more stable under internal pressure. And their solid structure allows them to withstand higher pressure and temperature. Therefore, blind flanges are widely used in the oil and gas industry to seal pipe ends or equipment openings, preventing fluid flow and making system maintenance, repair, and pressure testing easier.

F. Lap Joint Flange (LJ):

Our lap joint flange consists of two parts: the loose flange and the weld neck stub end. This design offers strong sealing and durability, allowing it to endure high pressure and low temperature. Therefore, LJ flanges are primarily applied in high-pressure pipeline systems within the oil and gas industry, particularly in situations involving the transport of liquids, gases, and chemicals, where ease of installation and maintenance is important.

2. Types of flanges used in the oil and gas industry based on material

As a skilled blind flange manufacturer, we provide a diverse selection of blind flanges n the oil and gas industry, available in materials such as super duplex stainless steel, duplex stainless steel, alloy steel, stainless steel, and carbon steel. Carbon steel or alloy steel flanges are typically used for high-pressure pipelines, while stainless steel, duplex steel, or nickel alloys are required in corrosive environments such as offshore oil fields.

A. Carbon Steel Flanges: ASTM A105, ASTM A350 LF2, ASTM A694

B. Stainless Steel Flanges: ASTM A182 F304/F304L, ASTM A182 F316/F316L, ASTM A182 F321

C. Alloy Steel Flanges: ASTM A182 F11/F22, ASTM A182 F5/F9, ASTM A182 F91

D. Low Temperature Steel Flanges: ASTM A350 LF2, ASTM A350 LF3, ASTM A182 F304L/F316L

E. Duplex Stainless Steel Flanges: ASTM A182 F51/F53, ASTM A182 F55

F. Nickel Alloy Flanges: Inconel 600/625, Hastelloy C22/C276, Monel 400

3. Types of flanges used in the oil and gas industry based on pressure class

The pressure class of a flange is determined by the maximum pressure it can withstand and is typically categorized according to ASME standards. In the oil and gas industry, the following flange pressure ratings are commonly applied to meet different operational needs: Different pressure classes are suited for various conditions, let us see them together.

A. Low to Medium Pressure: Class 150, Class 300

B. Medium to High Pressure: Class 600, Class 900

C. Ultra High Pressure: Class 1500, Class 2500

4. Types of flanges used in the oil and gas industry based on standards

We are a professional flange manufacturer, specializing in various types flanges in different international standards for the oil and gas industry, including ASME/ANSI Flanges, API Flanges, DIN Flanges, JIS Flanges, JIS Flanges. Just see them below in detail.

A. ASME/ANSI Flanges (ASME B16.5, ASME B16.47)

B. API Flanges (API 6A, API 17D, used for oil and gas wellhead equipment)

C. DIN Flanges (German standards, DIN 2633, DIN 2576)

D. JIS Flanges (Japanese standards, JIS B2220)

E. GB Flanges (Chinese National Standards, GB/T 9112-9124)

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....