What are ss(stainless steel) pipes

Stainless steel pipes are hollow, long, cylindrical steel tubes, primarily used for transporting fluids. They are widely used in industries such as petroleum, chemical, medical, food, light industry, and mechanical instrumentation, serving as fluid transportation pipelines and mechanical structural components. These pipes are made from acid-resistant and heat-resistant steel billets, which undergo processes like heating, piercing, sizing, hot rolling, and cutting during production.

Zizi Engineering Co Ltd. specializes in manufacturing various types of stainless steel pipes, including seamless and welded stainless steel pipes, as well as stainless steel pipe fittings. The materials used include 304, 312, 316, and duplex stainless steel. We also produce specialty alloys, such as seamless and welded pipes made from nickel-based alloys. We are ISO9001 Quality Management System certified and operate a fully equipped physical and chemical testing center. Our quality assurance system strictly complies with international standards, including ASME/ASTM (USA), JIS (Japan), DIN (Germany), EN (Europe), and GB/NB (China). Over the years, we have established long-term partnerships with numerous domestic and international clients. We specialize in delivering customized products tailored to customer requirements while ensuring the highest quality standards. For inquiries or further information, please feel free to contact us.

Different types of SS(stainless steel) pipes

We produce and sell a wide range of stainless steel pipes, offering various types and specifications based on different classification methods. Below, we will provide a detailed introduction to these methods to help you better understand the types and applications of stainless steel pipes.

1. SS(stainless steel) pipes based on material

304 stainless steel pipe:

Our 304 stainless steel pipe is one of the most common and widely used stainless steel pipes. It contains 18% chromium (Cr) and 8% nickel (Ni), which classifies it as part of the austenitic stainless steel family. They are widely used in industries such as chemical processing, marine engineering, pharmaceuticals, and seawater cooling systems.

316 stainless steel pipe:

Our 316 stainless steel pipes offer better corrosion resistance than 304 stainless steel pipes. They contain 2-3% molybdenum (Mo), 16-18% chromium (Cr), and 10-14% nickel (Ni). They are widely used in industries such as chemical processing, marine engineering, pharmaceuticals, and seawater cooling systems.

321 stainless steel pipe:

Our 321 stainless steel pipes are titanium-stabilized stainless steel pipes, made by adding titanium (Ti) to the 304 composition. They contain approximately 17-19% chromium (Cr) and 9-12% nickel (Ni), providing excellent high-temperature and corrosion resistance. These pipes are widely used in industries such as aviation, chemical processing, automotive manufacturing, and high-temperature equipment.

2205 stainless steel pipes:

Our 2205 stainless steel pipes are a type of duplex stainless steel pipe, offering high strength and excellent corrosion resistance. Duplex stainless steel contains 22% chromium (Cr), 5% nickel (Ni), 3% molybdenum (Mo), and a small amount of nitrogen (N). These pipes are ideal for industries such as marine engineering, chemical processing, oil, and natural gas, and are widely used in environments requiring high strength and corrosion resistance.

2. SS(stainless steel) pipes based on production method

Our stainless steel pipes are divided into two main categories based on production methods: seamless stainless steel pipes and welded stainless steel pipes.

Seamless stainless steel pipes:

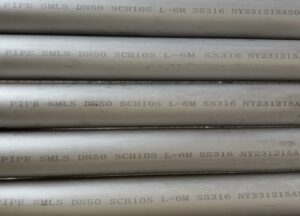

Our seamless stainless steel pipes are manufactured through hot rolling or cold drawing processes, featuring no weld seams on the pipe wall. They provide high strength and are ideal for high-pressure and high-temperature environments.

Welded stainless steel pipes:

Our welded stainless steel pipes are produced by welding stainless steel plates, with common methods including ERW (Electric Resistance Welding), EFW (Electric Fusion Welding), and arc welding. Based on the weld seam shape, they are categorized into straight seam welded pipes and spiral welded pipes, the latter being typically used for large-diameter pipelines.

3. SS(stainless steel) pipes based on application

Sanitary stainless steel pipes:

Our sanitary stainless steel pipes are commonly used in the food, beverage, and pharmaceutical industries. They require a smooth, spotless surface for easy cleaning.

Industrial Stainless Steel Pipe:

Our industrial stainless steel pipes are used for general industrial applications, including industries such as chemical, oil, and natural gas.

Structural Stainless Steel Pipe:

Our structural stainless steel pipes are primarily used for building structures and load-bearing frameworks.

Heat Exchanger Tubes:

Our heat exchanger tubes are used in heat exchangers to transfer heat.

4. SS (stainless steel) pipes based on pipe schedule

Schedule 10 stainless steel pipes:

Our schedule 10 stainless steel pipes have thinner walls and are suitable for low-pressure environments.

Schedule 40 stainless steel pipes:

Our schedule 40 stainless steel pipes have medium wall thickness and are commonly used in general-pressure piping systems.

Schedule 80 stainless steel pipes:

Our schedule 80 stainless steel pipes have thicker walls and are designed for high-pressure environments.

5. SS (stainless steel) pipes based on surface treatment

The surface treatment of stainless steel pipes can improve their appearance and corrosion resistance. Based on the surface treatment method, our stainless steel pipes can be categorized into bright pipes, brushed pipes, and sandblasted pipes.

6. SS (stainless steel) pipes based on national standards

Different countries and regions have varying standards for stainless steel pipes. Based on national standards, our stainless steel pipes can be classified into Chinese standards (GB), American standards (ASTM), and European standards (EN), Japanese Standards (JIS), DIN, among others.

7. SS (stainless steel) pipes based on shape

We specialize in the production of stainless steel pipes in various shapes, such as round pipes, square pipes, rectangular pipes, and oval pipes.

8. Reliable SS (stainless steel) pipes supplier

We are a reliable stainless steel pipes supplier, we focus on the production of different types of ss (stainless steel) pipes. To be mentioned, we also produce a wide range of pipe fittings, including elbows, tees, crosses, flanges, and bends. Our products are manufactured to standards such as GB, ASME, ANSI, EN, and DIN, and can be customized to meet customer specifications or drawings. They are widely used in major national engineering projects, our products are exported to over 30 countries and regions, including Europe, North America, Africa, and the Middle East. If you have any requirements, please contact us.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....