ASTM A106 grade B pipe is the standard specification for seamless carbon steel pipe used for high-temperature services. It includes three grades: A, B, and C, with Grade B being commonly used. This type of pipe finds applications in various industries, including pipeline systems for oil and gas, water, and mineral slurry transmission. It is also used in boiler systems and for construction and structural purposes.

ASTM A106 Grade B Pipe Standard

Scope

This specification covers seamless carbon steel pipe for high-temperature service(Note l)in NPS 1/8 to NPS 48 inclusive, with nominal(average)wall thickness as given in ANSI B 36.10.It shall be permissible to furnish pipe having other dimensions provided such pipe complies with all other requirements of this specification. Pipe ordered under this specification shall be suitable for bending, flanging, and similar forming operations, and for welding.When the steel is to be welded, it is presupposed that a welding procedure suitable to the grade of steel and intended use or service will be utilized(Note 2).

Note 1-It is suggested, consideration be given to possible graphitization.

Note 2-The purpose for which the pipe is to be used should be stated in the order, Grade A rather than Grade B or Grade C is the preferred grade for close coiling or cold bending. This note is not intended to prohibit the cold bending of Grade B seamless pipe.

ASTM A106 Grade B Pipe Specification

ASTM A106 carbon steel pipe specification is mainly applicable to seamless steel pipes size range of 1/8″ to 48″ (DN6 to DN1200). Wall thickness of these steel pipes must comply with ASME B36.10 standard.

| Processing Method | Seamless and Welded |

| Size Range | 1/8″- 48″ / DN6 – 1200 |

| Thickness Schedule | SCH 10, SCH 20, SCH 40, STD, XS, SCH 100, SCH 120, SCH 160, XXS |

| Length | 6m or 12 m or Random |

| Standard | ASME B36.10M |

| Surface Treatment | Blasting and Painting , Epoxy Powder FBE, 2PE, 3PE Coating |

| Material Grade | ASTM A106B / A53, API 5L B |

ASTM A106 B Material Analysis

The carbon content range of ASTM A106 Grade B pipe is 0.3%. Carbon is a key element that affects the strength and hardness of steel. Within this content range, ASTM A106 B material can achieve good strength while maintaining a certain toughness.

| CHEMICAL | LIMITS | C | Mn | P | S | Cu | Ni | Cr | Mo | V | Si |

| ASTM A106B | MIN | 0.29 | 0.10 | ||||||||

| MAX | 0.30 | 1.06 | 0.035 | 0.04 | 0.40 | 0.400 | 0.40 | 0.15 | 0.080 |

The minimum tensile strength of ASTM A106 Grade B pipe is 415 MPa. Tensile strength is the maximum stress that a material can withstand during stretching. The tensile strength of A106 B ensures that the material will not break easily when subjected to tensile loads.

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A106 GR B | 415 min | 240 min | 22 min |

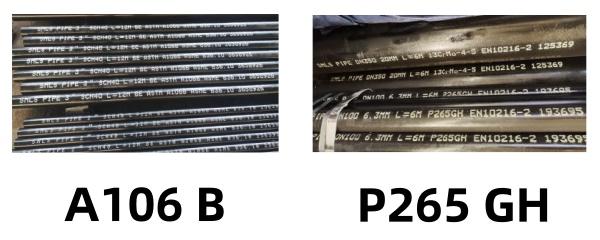

Equivalent Material of ASTM A106 Grade B Carbon Steel Pipes

| Former | New | |||

| Execution | Standard | Material | Standard | Material |

| Seamless | EN 10216-2 | P265GH | ASTM A106 | GRADE B |

A106 Pipe vs A53 Pipe

| Grade A | Grade B | Grade C | ||

| ASTM A53 | Tenside strength, min, psi (MPa) | 48000(330) | 60000(415) | |

| Yield strength, min, psi (MPa) | 30000(205) | 35000(240) | ||

| ASTM A106 | Tenside strength, min, psi (MPa) | 48000(330) | 60000(415) | 70000(485) |

| Yield strength, min, psi (MPa) | 30000(205) | 35000(240) | 40000(275) | |

Process

●Killed steel, with primary melting process being open-hearth, basic-oxygen, or electric-furnace, possibly combined with separate degassing or refining.

●Steel cast in ingots or strand cast is permissible.

●Hot-finished pipe need not be heat treated.

●Cold-drawn pipe shall be heat treated after the final cold draw pass.

Advantages of ASTM A106 Grade B Pipe

High-Temperature Resistance: ASTM A106 Grade B tubes are specifically designed to withstand high temperatures, making them suitable for use in applications involving elevated operating temperatures.

Superior Strength: These tubes exhibit exceptional tensile strength and yield strength, ensuring structural integrity and longevity even in demanding conditions.

Corrosion Resistance: ASTM A106 Grade B tubes provide good resistance to corrosion, enhancing their durability and performance in corrosive environments.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....