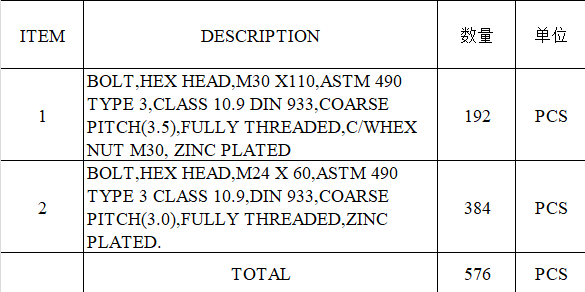

In July, Ms Sylvia from NHAN VIET ICS JSC in Vietnam were sourcing for the stud bolts and nuts:

Our price is very competitive , and reward the PO successfully. Meanwhile, we offer the FORM E and CO certification issued by the official goverment in order to reduce the custom clearance tax, our partner is very pleased with that.

ASTM A490 Type 3 Heavy Hex Bolts Specification

ASTM A490 bolts are heavy hex bolts made of alloy steel with a flat bearing surface, washer faced, and chamfered point. They are used in structural steel joints in heavy construction applications that require greater yield and tensile strengths than those of an A325 bolt are required. They are available in diameters ranging from ½” up to 1-1/2” and come in two types.

Type 1 bolts are made from alloy steel, and Type 3 is made from a weathering steel, which is approximately twice as resistant to corrosion as Type 1. These Type 3 A490 bolts shall be marked “A490” to set them apart from standard A490 bolts.

A490 Types

| TYPE 1 | Medium carbon and alloy steel. |

| TYPE 2 | Withdrawn in 2002. |

| TYPE 3 | Weathering steel. |

| M | Metric A490. |

A490 ASTM A490 Type 3 Chemical Properties

| Chemical Requirements for Type 3 Bolts | ||

| Element | Heat Analysis, % | Product Analysis, % |

| Carbon | ||

| Sizes 0.75 in. and smaller | 0.20–0.53 | 0.19–0.55 |

| Sizes larger than 0.75 in. | 0.30–0.53 | 0.28–0.55 |

| Manganese, min | 0.40 | 0.37 |

| Phosphorus, max | 0.035 | 0.040 |

| Sulfur, max | 0.040 | 0.045 |

| Copper | 0.20–0.60 | 0.17–0.63 |

| Chromium, min | 0.45 | 0.42 |

| Nickel, min | 0.20 | 0.17 |

| or | ||

| Molybdenum, min | 0.15 | 0.14 |

A490 ASTM A490 Type 3 Mechanical Properties

| Size | Tensile, ksi | Yield, ksi | Elong. %, min | RA %, min |

| 1/2 – 1-1/2 | 150-173 | 130 | 14 | 40 |

Heavy Hex Bolts Tensile Properties

| Tensile Load Requirements for Bolts Tested Full-Size | |||||

| Bolt Size,Threads per Inch,and Series Designation |

Stress Area,Ain² | Tensile Load B lbf | Proof Load B | Allermative Proof Load,B lbf |

|

| min | max | Length Measurement Method | Yield Strength Method |

||

| Column 1 | Column 2 | Column 3 | Column4 | 0dumn 5 | Column 6 |

| 1/2 -13 UNC | 0.142 | 21300 | 24600 | 17050 | 18500 |

| 5/8 -11 UNC | 0.226 | 33900 | 39100 | 27100 | 29400 |

| 3/4 -10 UNC | 0.334 | 50100 | 57800 | 40100 | 43400 |

| 7/8 -9 UNC | 0.462 | 69300 | 79950 | 55450 | 60100 |

| 1-8 UNC | 0.606 | 90900 | 104850 | 72700 | 78800 |

| 1 1/8 -7 UNC | 0.763 | 114450 | 132.000 | 91550 | 99200 |

| 11/4 -7 UNC | 0.969 | 145350 | 167680 | 16.300 | 26000 |

| 13/8 -6 UNC | 1.155 | 173250 | 199850 | 138600 | 150200 |

| 11/2 -6 UNC | 1.405 | 210750 | 243100 | 168600 | 182600 |

A The stress area is calculated as follows:

A.=0.7854[D-(0.9743/n)]2

where:

A – stress area, in.2

B – nominal bolt size, and

C – threads per inch.

B Loads tabulated and loads to be used for tests of full-size bolts larger than 1% in. in diameter are based on the following.

Inspecting ASTM A490 Type 3 Heavy Hex Bolts

Dimensional measurement:

Use measuring tools such as calipers and micrometers to check the dimensions of the bolts, including diameter, length, thread size, etc.

Ensure that the dimensions meet the relevant standards and design requirements.

Appearance inspection:

Visually inspect the surface of the bolts to check for defects such as cracks, scratches, rust, etc.

Check whether the threads are complete and the head shape is correct.

Heavy Hex Bolts Key Advantages

Enhanced Corrosion Resistance:

High Strength:

Suitability for Outdoor Environments:

Reduced Maintenance

Important Considerations:

While the weathering steel provides corrosion resistance, it’s essential to understand that it’s designed for specific environmental conditions. They are not suitable for all environments, particularly those with excessive chloride exposure (e.g., coastal areas with high salt content).

The selection of compatible washers and nuts is crucial for optimum performance.

It is very important to remember that certain coatings can cause hydrogen embitterment in high strength bolts, like A490 bolts, and are therefor prohibited.

In essence, ASTM A490 Type 3 bolts offer a combination of high strength and improved corrosion resistance, making them a reliable choice for demanding structural applications.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....