Lap

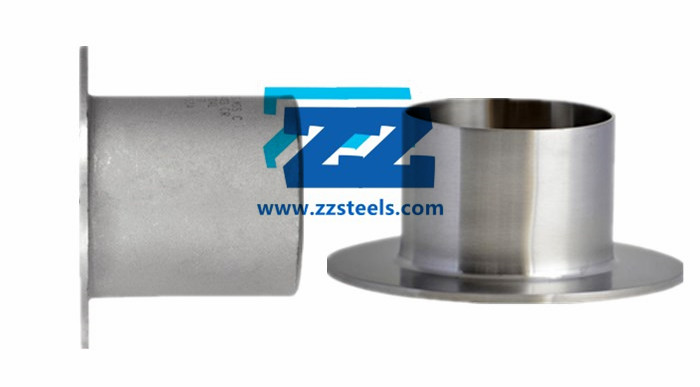

Joint Stub End Type A

Type A lap joint stub end is used with lap joint flanges to replace welded flanges. This combination is common in medium pressure and temperature pipelines with corrosive medium.

Stub end belongs to buttweld fittings, and there are mainly two standard for stub end fabrication. One is ASME B16.9, which is the most common used standard for buttweld pipe fittings. The other is MSS-SP-43, a specification standard for Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications.

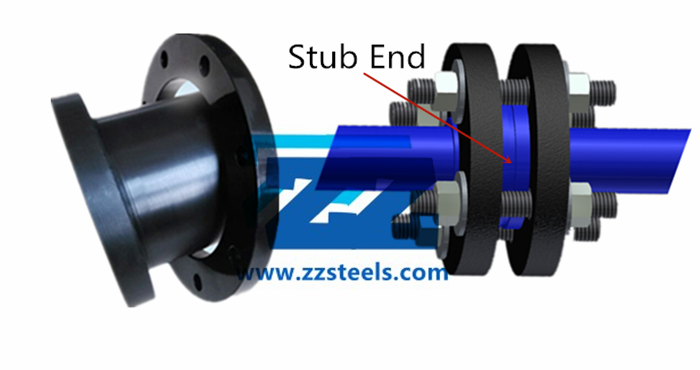

How to Use Lap Joint Stub End?

First sliding the flange over the pipe or stub end, then welding the stub end to the pipe so that the flange can be free to rotate around the stub end.

Stub

End Catalog

Lap Joint stub end has different types, and based on the length they are also available in long pattern and short pattern. Type A stub end and Type B stub end are more prevalent.

Type A Stub End

- Used with standard lap joint flange.

- Lap thickness is larger than or equal to pipe wall thickness.

- Outside corner radius is accommodated to the lap joint flange, inside corner is squared.

- Machined serrated face.

Type

B Stub End

- Suit

for slip on flanges acting as lap joint flanges. - Lap

thickness is greater than or equal to the wall thickness of connection pipes. - Outside

corner radius is small in order to receive slip on flange acting as a backup

flange, inner corner is square. - Machined

serrated face.

Type

C Stub End

- Used with lap joint flanges and slip on flanges.

- Lap thickness is 75% of connection pipes.

- It is flared and the radius can be closed to square if it’s necessary.

- Smooth surface.

Lap Joint Stub End Long Pattern

Long pattern lap joint stub end also called ASA-A stub end, it is available in standard and extra heavy wall thickness.

Lap Joint Stub End Short Pattern

It has another name MSS-A stub end, this type is available in all wall thicknesses. Both long pattern and short pattern are used with lap joint flanges.

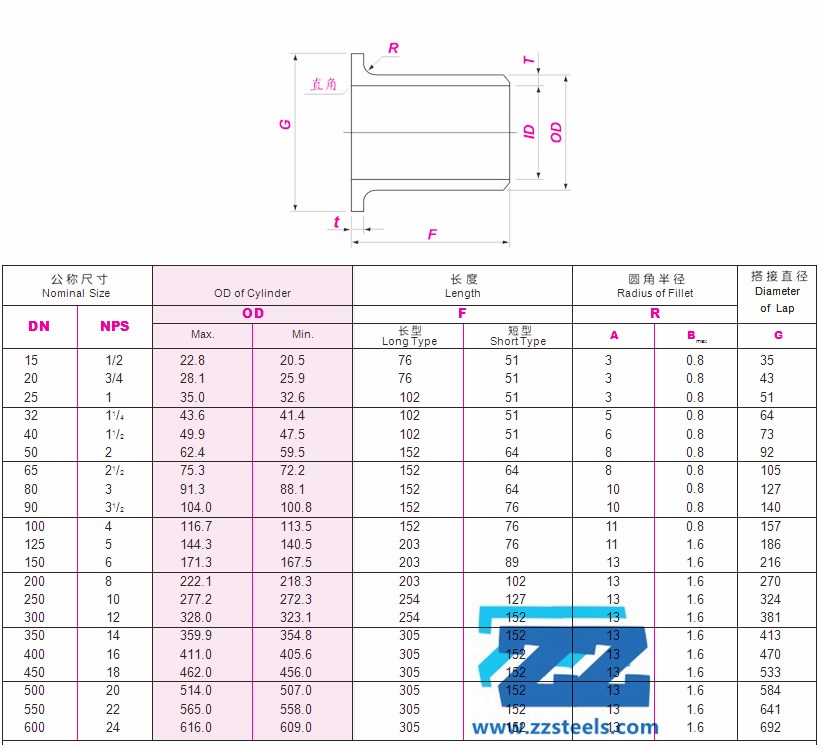

ASME B16.9 Stub End Dimensions

Advantages

of Lap Joint Stub End

Cost Benefits

Stub end is directly contact with pipes and medium whereas the flanges doesn’t. Therefore, the material grades of stub ends should satisfy the design and service conditions, while flanges can be made of lower grades to save the total cost.

Installation Advantages

The usage of lap joint stub end makes flanges can be rotated which is beneficial for aligning bolt holes. It also can adapt different thickness and material grades pipe to be connected.

Buying

tips for Lap Joint Stub End

Size

1/2″

to 48″ / DN15 to DN600

Wall thickness / Schedule

Sch

10s, 20, STD, 40, 80, 160, XXS

Type

Type

A, Type B, Type C

Length

Long Pattern and Short Pattern

Design Standard

ASME

B16.9, MSS SP 43

Material Grades

Stainless Steel: A403 WP304, WP316, WP317, WP321, WP310

Carbon

Steel: ASTM A234 WPB, A860 WPHY42, WHPY52, WPHY60, WHPY65, WPHY70.

Low

Temp Carbon Steel: ASTM A420 WPL3,WPL6, WPL9

Alloy

Steel: A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Duplex Stainless Steel: UNS S31803, S32205, S32550, S32750, S32760

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....