ASTM A105N Slip On Flange

A new customer comes from Singapore placed an order for 4 inch ASTM A105N Slip On Flange Class 300 which is common and useful in the project. Luckily, clients take and trust us as professional and experienced manufacturer and exporter.

Slip on Flange are usually described as SO Flange . It is a kind of optional flange with the properties of simple in structure and material saving. Hence, it suits for the connection of medium and low pressure vessels and pipes.

However, every product has advantage and defect. The main design defect of Slip On Flange is that not guarantee non-leakage. Therefore, we will try to improve the performance in the production and make it work best.

A105N Slip On Raised Face Flange

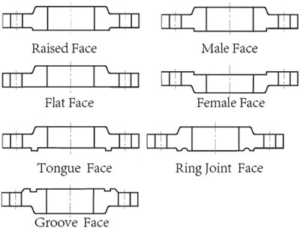

It refers to raised face and material . We will know N means normalizing. Same as all forged steel fittings. RF (raised face) is one seal type of flange. It is the most common type, its gasket surface is raised above the bolting circle face.

A105N Slip On Flat Face Flange

FF means flat face. It is another common seal type of flange. FF flange has a gasket surface in the same plane as the bolting circle face, it usually mates with flange or flanged fitting. And flat face flanges can’t be bolted to a raised face flange.

A105N Slip On Ring Type Joint Flange

There is another seal type RTJ (ring-type joint), it has a raised gasket face with the different ring groove machined in this face, RTJ flange can’t matched to RF flange or FF flange.

Flange Seal Type

Forged Flange Pressure

Zizi exported Cl150 Slip on Flange RF A105N and CL600 SOFF Flange A350 LF2 for our customers from Philippines and Malaysia last month. The pressure is an important factor which influences the weight of flange. In the same diameter, the higher the pressure, the heavier the weight, so as the flange thickness. And the pressure rating determines the height of the RF. The pressure grades are 150#, 300#, 600#, 900# and 1500#.

A105N CL600 Flange

A105N CL150 Flange

Industrial Flange Standard

Zizi manufactures flange according to standard ASME B16.5, ANSI B16.5 is its another name. So ANSI B16.5 A105N Slip On Flange and ASME B16.5 Slip-On Flange are the same thing. ANIS is American National Standards Institute, ASME is American Society of Mechanical Engineers. Both of them accepted this standard.

Flanges Surface

To make the A105N Slip On Flange against anti rust for long time. Client will buy galvanized slip on flange in material of A350 LF2 and A105N. Why galvanized flange is popular? It can be corrosion protection as good as stainless steel flange. But stainless steel flange is very expensive. Usually the surface for carbon steel flange are anti rust oil and painting.

Galvanized Flange

What is A350 LF2 Slip On Flange

Same as A105N Slip On Flange, A350 LF2 slip on flange is also a carbon steel flange. It is low temperature Forged Flange and impact tested at -50°F. Forging Temperature should be 900 – 1200°C.

ASTM A350 LF2 has good machinability, dependent on condition, and operations such as sawing, turning, broaching, milling. ASTM A350 LF2 slip on flange is readily weldable by any technique.

Forged Flange Quality Inspection

Zizi Engineering not only has abundant producing experience, but also put the quality on top.

Firstly, inspect the quality of steel material, we will use original steel material that meet the appropriate standards.

Secondly, regular inspects and replaces production equipment to eliminate the possibility of rough manufacturing

When the product is finished, our QA/QC will check each one carefully in case the defective goods was delivered to our customers. If customers request, we can deliver the inspection to third parties. Such as BV, SGS, TUV and so on.

A105N Flange Inspection

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....